|

Timing belt, or cam belt (informal useage) is a part of an internal combustion engine that controls the timing of the engine's valves. Some engines, like the flat-4 Volkswagen air cooled engine, use timing gears. The term "timing belt" is also used for the more general case of any flat belt with integral teeth. Such belts are used for power transmission or to interchange rotary motion and linear motion, where either high loads or maintaining a specific drive ratio are important. A common non-automotive application is in linear positioning systems or bicycle drives.

In the internal combustion engine application, the timing belt connects the crankshaft to the camshaft(s), which in turn controls the opening and closing of the engine's valves. A four-stroke engine requires that the valves open and close once every other revolution of the crankshaft. The timing belt does this. It has teeth to turn the camshaft(s) synchronised with the crankshaft, and is specifically designed for a particular engine. In some engine designs, the timing belt may also be used to drive other engine components such as the water pump and oil pump.

Gear or chain systems can also be used to connect the crankshaft to the camshaft at the correct timing. However gears and shafts constrain the relative location of the crankshaft and camshafts. Even where the crankshaft and camshaft(s) are very close together, as in pushrod engines, most engine designers use a short chain drive rather than a direct gear drive. This is because gear drives suffer from frequent torque reversal as the cam profiles "kick back" against the drive from the crank, leading to excessive noise and wear. Fibre gears, with more resilience, are preferred to steel gears where direct drive has to be used. A belt or chain allows much more flexibility in the relative locations of the crankshaft and camshafts. Camshaft drives, whether gears, belts or chains are also able to even out wear, since the chain or belt can be made such that the number of teeth on the belt is coprime to the number of teeth on the crankshaft and camshaft sprockets, thus ensuring that each tooth on sprocket does not end up on the same tooth on the belt repeatedly.

While chains and gears may be more durable, rubber belts are quieter in their operation (in most modern engines the noise difference is negligible), are less expensive and are mechanically more efficient, by dint of being considerably lighter, when compared with a gear or chain system. Also, timing belts do not require lubrication, which is essential with a timing chain or gears. A timing belt is a specific application of a synchronous belt used to transmit rotational power synchronously.

Timing belts are typically covered by plastic timing belt covers which require removal to carry out visual inspection. Engine manufacturers recommend replacement at specific intervals. [1] The manufacturer may also recommend the replacement of other parts, such as the water pump, when the timing belt is replaced because the additional cost to replace the water pump is negligible compared to the cost of accessing the timing belt. In an interference engine, or one whose valves extend into the path of the piston, failure of the timing belt (or timing chain) invariably results in costly and, in some cases, irreparable engine damage, as some valves will be held open when they should not be and thus will be struck by the pistons.

Indicators that the timing chain may need to be replaced include a rattling noise from the front of the engine.

Interference

Depending on the design of the engine, the piston and valve paths may "interfere" with one another, and incorrect timing in their movements may result in the piston and valves colliding. (Such designs are also called "interference head" or "interference engines", and include virtually all diesel engines. Conversely, non-interfering engines, such as the Mazda B engine, are called "free-wheeling" or "non-interference" engines.)

In interference designs, regular service is especially important as incorrect timing may result in the pistons and valves colliding and causing extensive engine damage and therefore costly repairs. The piston will likely bend the valves or if a piece of valve or piston is broken off within the cylinder, the broken piece may cause severe damage within the cylinder, often also affecting the connecting rods. Some manufacturers, such as Nissan, have switched back to timing chains for the majority of their engines because of the breakage problems associated with belts. However, in some newer engines, timing belts are designed to last the effective life of the engine.[citation needed] Other manufacturers, such as Toyota, use a mix: timing chains on their interference engines and timing belts on their non-interference engines.

When a timing belt is replaced, care must be taken to ensure that the valve and piston movements are correctly synchronised. The usual failure mode of a timing belt is stripped teeth (which leaves a smooth section of belt where the drive cog will slip) rather than an outright snapping of the belt, which is very uncommon.[citation needed] Correct belt tension is critical - too loose and the belt will whip, too tight and it will whine and put excess strain on the bearings of the cogs. In either case belt life will be drastically shortened.

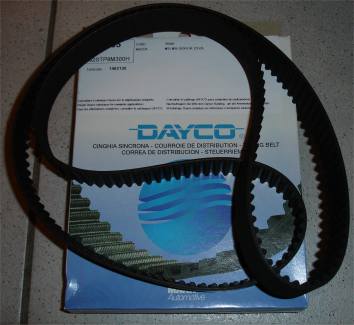

A timing belt is typically rubber with high-tensile fibres (e.g. fiberglass or Twaron / Kevlar) running the length of the belt.

Rubber degrades with higher temperatures, and with contact with motor oil. Thus the life expectancy of a timing belt is lowered in hot or leaky engines. Newer or more expensive belts are made of temperature resistant materials such as "highly-saturated nitrile" (HSN).[citation needed] The life of the reinforcing cords is also greatly affected by water and antifreeze. This means that special precautions must be taken for off road applications to allow water to drain away or be sealed from contact with the belt.

Older belts have trapezoid shaped teeth. Newer manufacturing techniques allow for curved teeth that are quieter and last longer.

Aftermarket timing belts may be used to alter engine performance. OEM timing belts "will stretch at high rpm, retarding the cam and therefore the ignition." Stronger, aftermarket belts, will not stretch and the timing is preserved. In terms of engine design, "shortening the width of the timing belt reduce weight and friction".

The first known timing belt was used in 1945. The German Glas 1004 was the first mass produced vehicle to use a timing belt in 1962. The first American vehicle to use a timing belt was the 1966 Pontiac Tempest. In 1966, Vauxhall started production of the Slant Four overhead cam four-cylinder design which used a timing belt, a configuration that is now used in the vast majority of cars built today.

|