|

In this case I'm talking about gears meaning 'toothed wheel' as oppose to gears as in 'my car has 5 gears'. A gear (or cog, or sprocket) in its most basic form is a flat circular object that has teeth cut into the edge of it. The most basic type of gear is called a spur gear, and it has straight-cut teeth, where the angle of the teeth is parallel to the axis of the gear. Wider gears and those that are cut for smoother meshing are often cut with the teeth at an angle, and these are called helical gears. Because of the angle of cut, helical gear teeth have a much more gradual engagement with each other, and as such they operate a lot more smoothly and quietly than spur gears. Gearboxes for cars and motorbikes almost always use helical gears because of this. A side effect of helical gears is that if the teeth are cut at the correct angle - 45 degrees - a pair of gears can be meshed together perpendicular to each other. This is a useful method of changing the direction of movement or thrust in a mechanical system. Another method would be to use bevel gears.

The number of teeth cut into the edge of a gear determines its scalar relative to other gears in a mechanical system. For example, if you mesh together a 20-tooth gear and a 10-tooth gear, then drive the 20-tooth gear for one rotation, it will cause the 10-tooth gear to turn twice. In this case, the larger gear is the input gear. Each tooth on the input gear meshes with one tooth on the output gear. There are 20 teeth on the input gear and only 10 on the output gear. It follows then that for one rotation of the input gear, the output gear will turn twice. This creates a gear ratio of 20 teeth to 10 - 20:10 or 2:1. This is known as gearing up .

Gearing down is exactly the same only the input gear is now the one with the least number of teeth. The output gear is the larger one and now, for every turn of the input gear, the output gear turns half a revolution. In this case it becomes a gear ratio of 10:20, or 1:2.

By meshing many gears together of different sizes, you can create a mechanical system to gear up or gear down the number of rotations very quickly. As a final example, imagine an input gear with 20 teeth, a secondary gear with 40 teeth and a final gear with 50 teeth. From the input gear to the secondary gear, the ratio is 1:2 - half. From the second gear to the final gear, the ratio is 4:5 - four fifths. The total gear ratio for this system is (1/2) * (4/5) which works out to be 1/2.5, or 0.4. ie. for one turn of the input gear, the output gear turns 0.4 times.

Collections of helical gears in a gearbox are what give the gearing down of the speed of the engine crank to the final speed of the output shaft from the gearbox. The table below shows some example gear ratios for a 5-speed manual gearbox (in this case a Subaru Impreza).

Final drive - calculating speed from gearbox ratios . It's important to note that in almost all vehicles there is also a final reduction gear. This is also called a final drive or a rear- or front-axle gear reduction and it's done in the differential with a small pinion gear and a large ring gear (see the section on differentials lower down the page). In the Subaru example above, it is 4.444:1. This is the final reduction from the output shaft of the gearbox to the driveshafts coming out of the differential to the wheels. So using the example above, in 5th gear, at 3000rpm, the gearbox output shaft spins at 4065rpm. This goes through a 4.444:1 reduction in the differential to give a wheel driveshaft rotation of 914rpm. For a Subaru, assume a wheel and tyre combo of 205/55R16 giving a circumference of 1.985m or 6.512ft (see The Wheel & Tyre Bible ). Each minute, the wheel spins 914 times meaning it moves the car (914 x 6.512ft) = 5951ft along the ground, or 1.127 miles. In an hour, that's (60minutes x 1.127miles) = 67.62. In other words, knowing the gearbox ratios and tyre sizes, you can figure out that at 3000rpm, this car will be doing 67mph in 5th gear.

Making those gears work together to make a gearbox

If you look at the image below you'll see a the internals of a generic gearbox. You can see the helical gears meshing with each other. The lower shaft in this image is called the layshaft - it's the one connected to the clutch - the one driven directly by the engine. The output shaft is the upper shaft in this image. To the uneducated eye, this looks like a mechanical nightmare. Once you get done with this section, you'll be able to look at this image and say with some authority, "Ah yes, that's a 5-speed gearbox".

So how can you tell? Well look at the output shaft. You can see 5 helical gears and 3 sets of selector forks. At the most basic level, that tells you this is a 5-speed box (note that my example has no reverse gear) But how does it work? It's actually a lot simpler than most people think although after reading the following explanation you might be in need of a brain massage.

With the clutch engaged (see the section on clutches below), the layshaft is always turning. All the helical gears on the layshaft are permanently attached to it so they all turn at the same rate. They mesh with a series of gears on the output shaft that are mounted on sliprings so they actually spin around the output shaft without turning it. Look closely at the selector forks; you'll see they are slipped around a series of collars with teeth on the inside. Those are the dog gears and the teeth are the dog teeth. The dog gears are mounted to the output shaft on a splined section which allows them to slide back and forth. When you move the gear stick, a series of mechanical pushrod connections move the various selector forks, sliding the dog gears back and forth. In the image below, I've rendered a close-up of the area between third and fourth gear.

When the gearstick is moved to select fourth gear, the selector fork slides backwards. This slides the dog gear backwards on the splined shaft and the dog teeth engage with the teeth on the front of the helical fourth gear. This locks it to the dog gear which itself is locked to the output shaft with the splines. When the clutch is let out and the engine drives the layhshaft, all the gears turn as before but now the second helical gear is locked to the output shaft and voila - fourth gear.

Grinding gears. In the above example, to engage fourth gear, the dog gear is disengaged from the third helical gear and slides backwards to engage with the fourth helical gear. This is why you need a clutch and it's also the cause of the grinding noise from a gearbox when someone is cocking up their gearchange. The common misconception is that this grinding noise is the teeth of the gears grinding together. It isn't. Rather it's the sound of the teeth on the dog gears skipping across the dog teeth of the helical output gears and not managing to engage properly. This typically happens when the clutch is let out too soon and the gearbox is attempting to engage at the same time as it's trying to drive. Doesn't work. In older cars, it's the reason you needed to do something called double-clutching.

Double-clutching, or double-de-clutching (I've heard it called both) was a process that needed to happen on older gearboxes to avoid grinding the gears. First, you'd press the clutch to take the pressure off the dog teeth and allow the gear selector forks and dog gears to slide into neutral, away from the engaged helical gear. With the clutch pedal released, you'd 'blip' the engine to bring the revs up to the speed needed to engage the next gear, clutch-in and move the gear stick to slide the selector forks and dog gear to engage with the next helical gear.

The synchromesh - why you don't need to double-clutch. Synchros, synchro gears and synchromeshes - they're all basically the same thing. A synchro is a device that allows the dog gear to come up to a speed matching the helical gear before the dog teeth attempt to engage. In this way, you don't need to 'blip' the throttle and double-clutch to change gears because the synchro does the job of matching the speeds of the various gearbox components for you. To the right is a colour-coded cutaway part of my example gearbox. The green cone-shaped area is the syncho collar. It's attached to the red dog gear and slides with it. As it approaches the helical gear, it makes friction contact with the conical hole. The more contact it makes, the more it matches the rotation of the free-spinning helical gear to the speed of the output shaft before the teeth engage (because the helical gear is meshed with the gear on the layshaft, and the clutch is disengaged.)

So to sum up that very long-winded description, I've rendered up an animation - when you see parts of a gearbox moving in an animation, it'll make more sense to you. What we have here is a single gear being engaged. The layshaft from the clutch and engine is the blue shaft with the smaller helical gear attached to it - it's always turning. To start with, the larger helical gear is free-spinning on its slip ring around the red output shaft. As the gear stick is moved, the gold selector collar begins to slide the dog gear along the splines on the output shaft. As the synchromesh begins to engage the large helical gear, the dog gear starts to spin up to speed, as does the output shaft because of the splines. Once the speed of the dog gear and output shaft match the speed of the large helical gear, the dog teeth engage properly and the gear is locked into place. At the end of the animation, the blue layshaft is now driving the red output shaft and the gearbox is in gear. Now doesn't that make it easier to understand?

What about reverse?

Reverse gear is normally an extension of everything you've learned above but with one extra gear involved. Typically, there will be three gears that mesh together at one point in the gearbox instead of the customary two. There will be a gear each on the layshaft and output shaft, but there will be a small gear in between them called the idler gear. The inclusion of this extra mini gear causes the last helical gear on the output shaft to spin in the opposite direction to all the others. The principle of engaging reverse is the same as for any other gear - a dog gear is slid into place with a selector fork. Because the reverse gear is spinning in the opposite direction, when you let the clutch out, the gearbox output shaft spins the other way - in reverse. Simple. The image on the left here shows the same gearbox as above modified to have a reverse gear.

Before the gearbox - the clutch

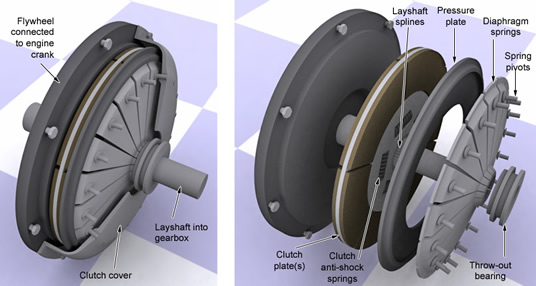

So now you have a basic idea of how gearing works there's a second item in your transmission that you need to understand - the clutch. The clutch is what enables you to change gears, and sit at traffic lights without stopping the engine. You need a clutch because your engine is running all the time which means the crank is spinning all the time. You need someway to disconnect this constantly-spinning crank from the gearbox, both to allow you to stand still as well as to allow you to change gears. The clutch is composed of three basic elements; the flywheel, the pressure plate and the clutch plate(s). The flywheel is attached to the end of the main crank and the clutch plates are attached to the gearbox layshaft using a spline. You'll need to look at my diagrams to understand the next bit because there are some other items involved in the basic operation of a clutch. (I've rendered the clutch cover in cutaway in the first image so you can the

|